Hit with shipping delays the past few weeks, we’re now back on track and have improved our process so we can ship even faster now.

If any of you shipped ammo in the past couple of weeks (other than Thursday and Friday last week) you would have seen a message like this one…

You’ll receive an email confirmation with a tracking number when your ammo is packaged and ready for carrier pickup. Please note, it is currently hunting season and we are short staffed. Please allow 5-7 business days for your ammo to ship out. If you need to prioritize your shipment for any reason, please reach out to customer support and we will do our best to accommodate your request.

If you are a new customer you might not know that our typical turnaround time is usually 1-2 business days… not five to seven! That wasn’t normal for us at all. We were buried in orders and couldn’t get ahead.

So what happened?

First of all, start with the fact that we have a small team, it is bigger now, but a month ago our warehouse team was only three people with two more that could fill in as needed. So that makes any absence a big deal for us.

It is bow hunting season and one of our warehouse guys was out hunting for 2 weeks in the Idaho backcountry. That reduced our core team down to two people. Then one of our warehouse staff (my daughter) left for art school in NJ… so now we were down to just one regular warehouse person with two more fill-ins.

With the increase in customers we’ve been seeing lately, that just wasn’t enough to keep up and we experienced a slow motion landslide where each day we couldn’t quite get through the backlog so it grew… and grew.

As the CEO, I blame myself for not taking action sooner knowing the storm was coming. Also as CEO I do what needs to be done, and there were many times during the past three weeks that I was out on the line picking orders, checking orders, or boxing them up for shipment. We even deployed some of our staff that isn’t normally in the warehouse to cover the shortfall like Tim our Chief Product Officer and Sarah our newest Customer Service Rep.

At our worst point we fell about 350 shipments behind which was about a 5 shipping day backlog for our previous warehouse staff (70-80 shipments per day was about max at the time). If any customer needed us to prioritize their shipment and contacted customer service, we were able to do that but it was an ugly situation for a while.

I’m happy to report that the situation is now cleared up and we have plans to get ammo out even faster than before. Sometimes a process needs to break so you can build it back better again. So that is exactly what we did.

First, we added more people. I mean A LOT more. We added six new warehouse employees that are available to do the picking, packing and shipping. We also added another shift manager to help manage all those new folks and move ammo around so it is placed efficiently in the warehouse.

In addition to more employees, we added more shipping stations. We went from two picking carts and two shipping stations to three and three – increasing our throughput by an additional 50%.

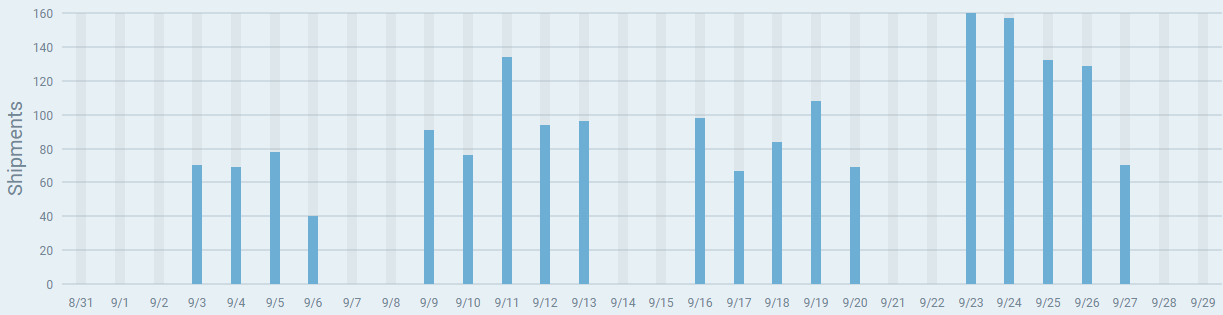

As you can see from the graph below, we went from averaging 60-80 shipments per day early in the month to doubling our throughput last week to 160 shipments/day:

That is a huge improvement! So with the crisis over, now on to the good part…

Same Day Fulfillment

In the past we aimed to get orders out in 1-2 business days. Even with our small crew we could usually hit that target unless there was an unusually large spike in orders. Going forward our target will be shipping out orders the SAME DAY they come in. We were actually able to achieve this on Friday. We cleared our backlog early, then as each new order came in, we got it picked, checked, and shipped.

After struggling with a landslide of orders, it was amazing to see us shipping orders out minutes after they arrived in our system. As Tom Cruise says in the movie Taps: “It’s beautiful man! Beautiful!”

With the current additional warehouse crew and additional stations I believe we can get 98% of shipments out the same day they come in, excluding weekends. There will always be a handful that we need to contact the customer about which will delay them so I can’t say 100% but we’ll strive for it.

Additional Warehouses = Faster Transit Times

While we are able to get shipments out the same day they come in, we are still at the mercy of UPS and Fedex transit times. In some cases this can be 5 business days to the Eastern side of the country. Obviously we don’t have the resources of Amazon, and we can’t ship ammunition via air but we DO have a plan…

More Warehouses!

Our current headquarters and single warehouse is located in Idaho. For many years we’ve talked about adding warehouses around the country. We are just about to that point now with our tremendous recent growth.

So the plan will be to add warehouses in strategic locations around the country so our customers can get their ammo in their hands in 3 days no matter where they are. Eventually we believe we’ll be able to cut this time down to 2 days but it will take a lot of resources and is really more of a 5-10 year plan.

More warehouses around the country also serves another purpose – diversification. With natural and man-made disasters happening in all corners of the country, more warehouses means we can spread out our ammunition inventory so it is protected even more. Just like we preach about not having all of your eggs in one basket, we will be able to do the same with a bunch of new warehouse locations.

With faster shipping times and more warehouses your ammunition will be safer, more diversified, and get to you quicker when requested. Making it truly, “ammunition that’s there when you need it.”

Read the full article here